Training and Certification

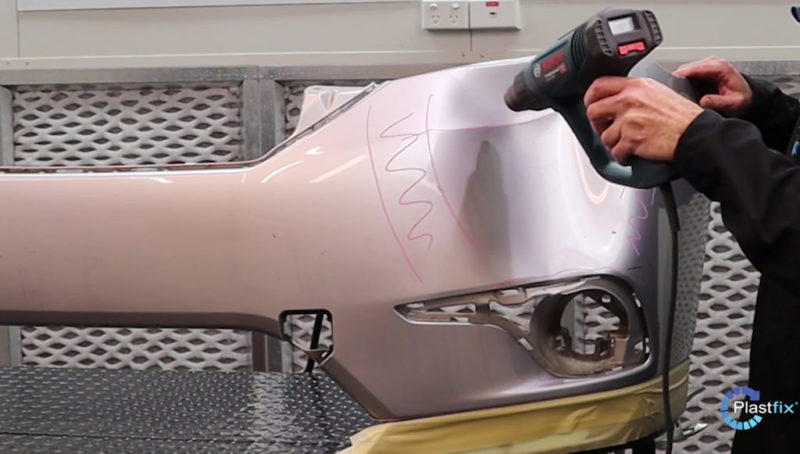

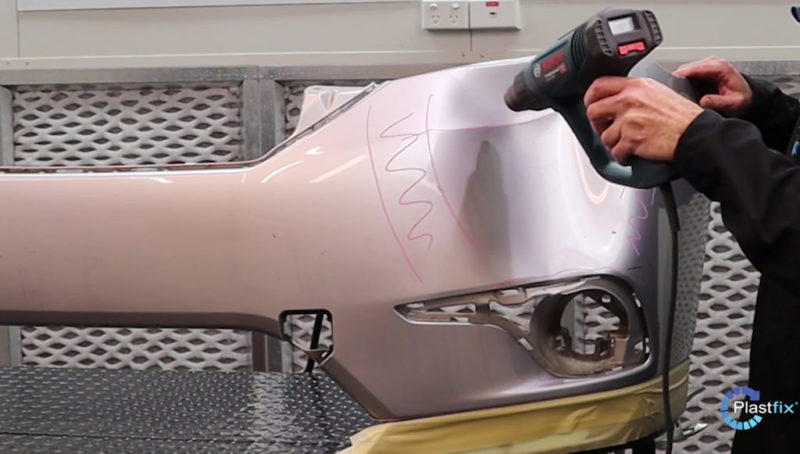

Plastfix has built a large library of over 100 videos that detail the Plastfix Repair Process.

These training videos play a vital role in our ability to maintain our high standards of providing the most advanced and up to date training for Plastfix Technicians.

The company certifies our own plastic repair technicians and key operational staff with re-certification to ensure ongoing competency in the repair of new plastic materials and evolving Plastfix Repair Process.

Plastfix Online Training Courses

Managers Estimators Course

Understanding Plastic Impacts

Content: 17 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 8 Hours

Certificate of Attainment

Plastic Repairs Technician Course - Level I

Introductory

Content: 20 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 10 Hours

Certificate of Attainment

Plastic Repairs Technician Course - Level ll

Intermediate

Content: 19 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 10 Hours

Certificate of Attainment

Plastic Repairs Technician Course - Level lll

Professional

Content: 49 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 20 Hours

Lesson 1: Headlight Repairs

Headlight – Sanding, Priming and Finishing

Headlight – Lens Sanding and Polishing

Lesson 2: Heat Application and Reshaping

Lesson 3: Sanding of Repairs

Lesson 4: Alignment of tears and Tag Welding.

Lesson 5: Repair Procedures and Finishing of Repairs

Certificate of Attainment

Managers Estimators Course

Understanding Plastic Impacts

$150 USD + GST / VAT

Content: 17 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 8 Hours

Certificate of Attainment

Plastic Repairs Technician Course - Level I

Introductory

$150 USD + GST / VAT

Content: 20 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 10 Hours

Certificate of Attainment

Plastic Repairs Technician Course - Level lll

Professional

$200 USD + GST / VAT

Content: 49 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 20 Hours

Lesson 1: Headlight Repairs

Headlight – Sanding, Priming and Finishing

Headlight – Lens Sanding and Polishing

Lesson 2: Heat Application and Reshaping

Lesson 3: Sanding of Repairs

Lesson 4: Alignment of tears and Tag Welding.

Lesson 5: Repair Procedures and Finishing of Repairs

Certificate of Attainment

Plastic Repairs Technician Course - Level ll

Intermediate

$175 USD + GST / VAT

Content: 19 Videos, and Theory

Assessment: Virtual

Estimated Completion Time: up to 10 Hours

Certificate of Attainment